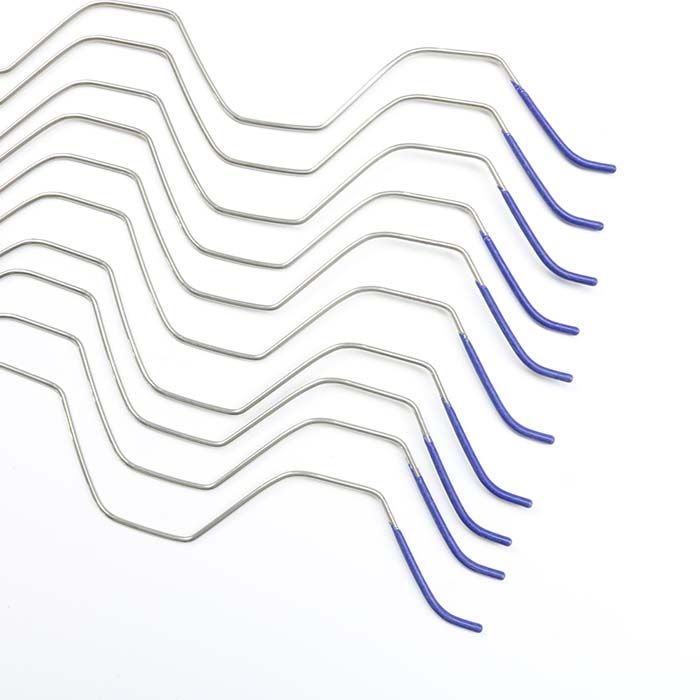

Stainless steel wiggle wire

Specification

| Model | Raw material | Spec. (Before coating) | Spec. (After coating) | Length (Laying) | Length (inserted in channel) | Coating Color | Treatment | Guarntee |

| stainless steel wire | φ2.3mm | φ2.9mm | 1.95m | 2.2m | None | None | 8 years |

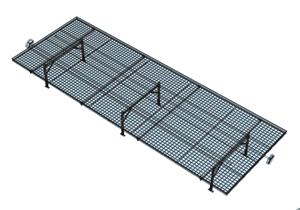

Product Details

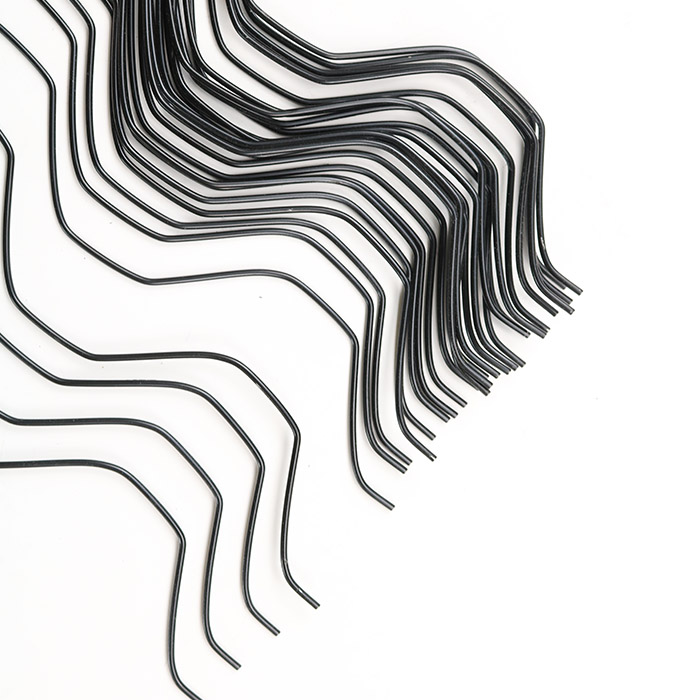

What is Wiggle Wire?

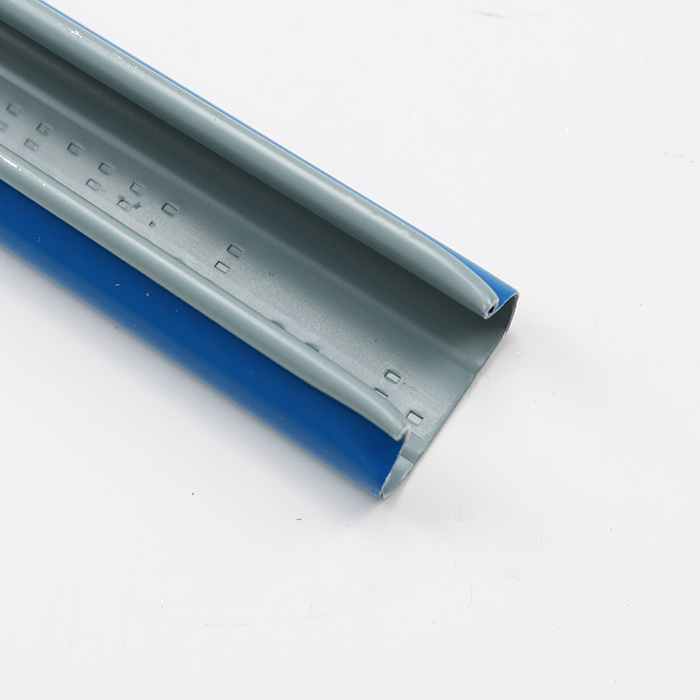

Wiggle Wire, commonly known as Spring Lock or Zigzag, is an economical and easy way to install greenhouse coverings, including polyethylene film, insect nets and shading screen, to a greenhouse structure. Wiggle Wire is widely used in conjunction with wiggle wire channel (or Lock channel) to form a tight and secure attachment of your greenhouse coverings.

The Advantages of GOODLOCK Wiggle Wire

Safety

* The cost of wiggle wire takes 1% of all greenhouse construction cost, but ensures 100% safety of greenhouse film.

* In recent years, 2-5 year’s guarantee film is widely used, which is easily broken. To make some improvements, GOODLOCK Wiggle Wire, coated by imported engineering plastic powder with UV stabilization, can do better performance to fix film.

* Common wiggle wire’s ends are too sharp and easily breaking film while GOODLOCK Wiggle Wire’s ends are thicker and rounded, ensuring easy film installation and not destroy film.

Why most buyers choose GOODLOCK Wiggle Wire ?

* Factory direct sales, we are the manufacturer!

* Large stock, Fast delivery!

* Over 10 years’ experience, top quality with competitive price!

* The technical consulting service and operation guidance would be provided!

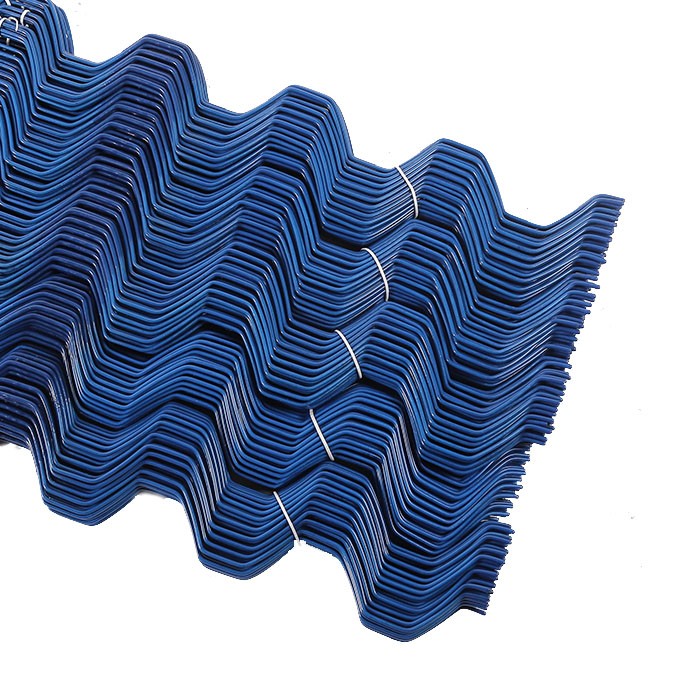

* Customization is also available in high demand!

* 6-8 years guarantee, best after-sale service!

* High efficiency! Laborsaving! Fast!

Selling point

* PE coated wiggle wire, which is nontoxic and care for the film and operator.

* 1.9m of PE coated steel, thickness over 0.083”.

* Matching with locking channel (separately sold).

* Applicable for all kinds of film greenhouse.

* To fix the poly film or shade screen to the locking channels with minimal effort.

* Special 72B spring steel wire for durability.

Application

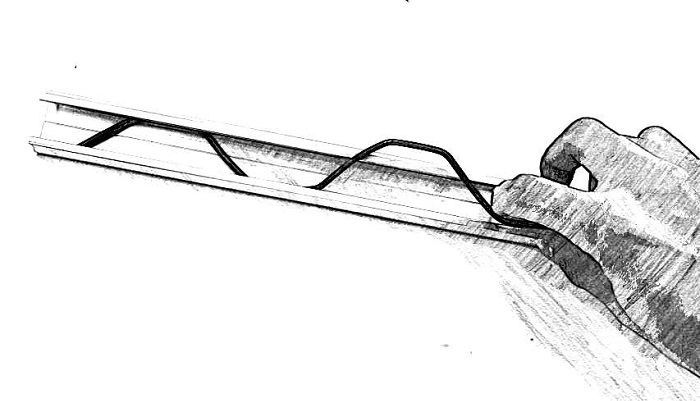

How to use

Package

Why Blue Wiggles have thicker ends?

When install the film with the Wiggle Wire, with thicker round ends, no damage to the film and hand.

High efficient to fix the film and save time, extend the service life of the film inside the profile.

1% of improvement derived from 99% hardworking

GOODLOCK applying the Japanese standard, produced under strict management system, it has been exported worldwide 10 years successfully. Every small improvement for the Wiggle Wire, we pay the hard work and test strictly.

We never forget our original intention, grope forward, insist innovation, filed so many patents. Continuous innovation and R&D will bring efficient and convenient products!